My partner and I played a lot of Outer Wilds during the peak of the COVID-19 pandemic, and it's probably no surprise that I fell in love with its charming characters and expansive universe. I decided to celebrate the game by embroidering its solar system.

Since Outer Wilds fans are especially touchy about spoilers, I should note that this project has them everywhere, I should probably note that you should read no further if you don't want any hints of what may come later in the game if you haven't already completed it and its DLC!

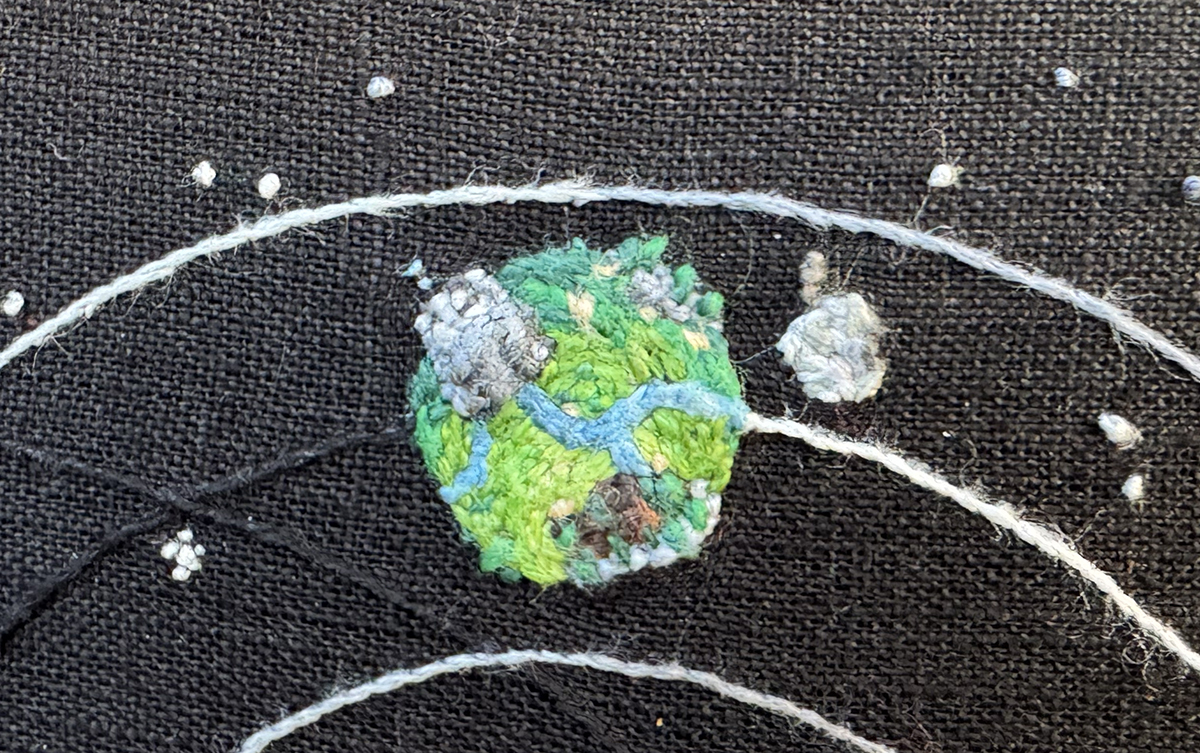

I based my Outer Wilds solar system design on where the planets are at about 9 minutes and 48 seconds into the loop, but everything is re-scaled - while maintaining the vibes of the original proportions - so the planets and background supernovas in the dying universe aren't tiny. I realize now that I have a pattern of adding hundreds of additional (and arguably unnecessary) French knots to my embroidery projects - I am non-sarcastically shocked that I made this choice right after doing thousands upon thousands of French knots for the Milky Way in my Northern Sky & Southern Sky quilts.

Since the Eye of the Universe and the Owlk's home both aren't in Hatchling's solar system, I did each in a separate hoop, too. I chose to represent the Eye with a blend of the symbols used by the Nomai and the Stranger's inhabitants, and I opted to represent the Owlk's home moon and the planet it orbits before they raided it to build the Stranger.

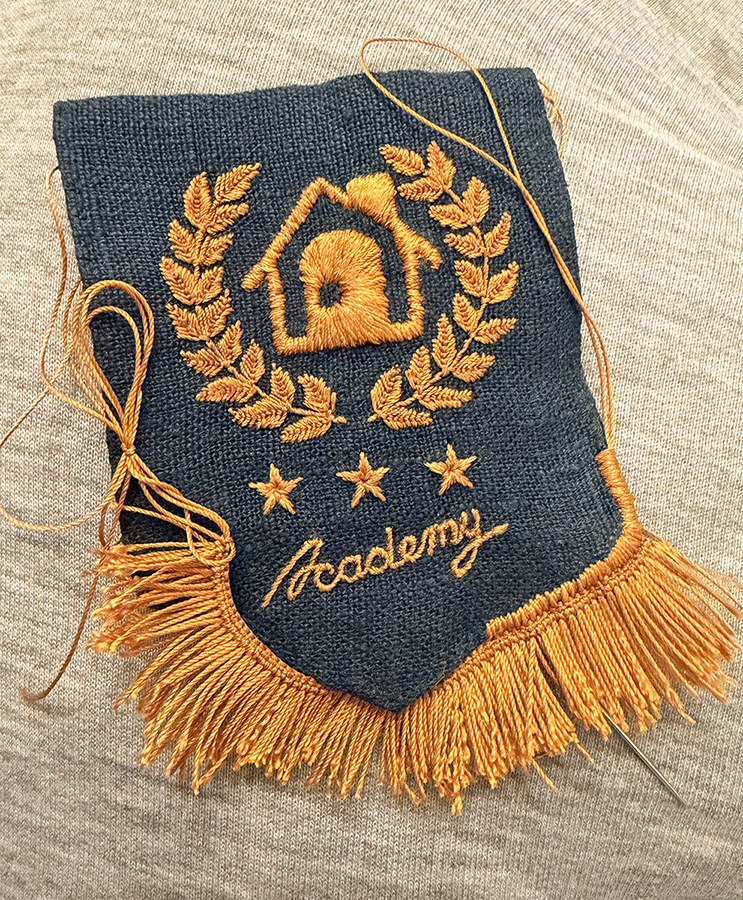

Each of the planets has a slightly different feel due to the stitches I chose. Here are some detail shots of the main hoop:

I've hung the three hoops together on a wall near my desk:

All in all, I ended up using 97 different linen threads in this project, including a handful of vintage ones and a highly variegated space-dyed thread that gave me access to 5 different colors and blends between them.

...and just in case that wasn't enough, I actually made this whole project twice, so I could give a copy to the friend who introduced me and my partner to this phenomenal game!

P.S. Since this is fan art, I don't feel comfortable publishing my design - sorry!