One of the things I love most about working in a community studio is hearing about other ceramists' experiences with new-to-me clay bodies. This has helped me feel confident in trying out many different clay bodies, and I now use a bunch of different clay bodies in my practice.

Yet there are too few commercial clay body reviews out in the world, even if you deep dive various topical forums! I figured my blog might be a good place to pass along my experiences to other interested ceramists, and I'll be starting with some colored stoneware offerings from Standard Clay Company today. I like working with each of these clays individually, and they also work well marbled together!

Note that I currently practice community in a studio that glaze fires to cone 6 in oxidation, so my observations reflect that.

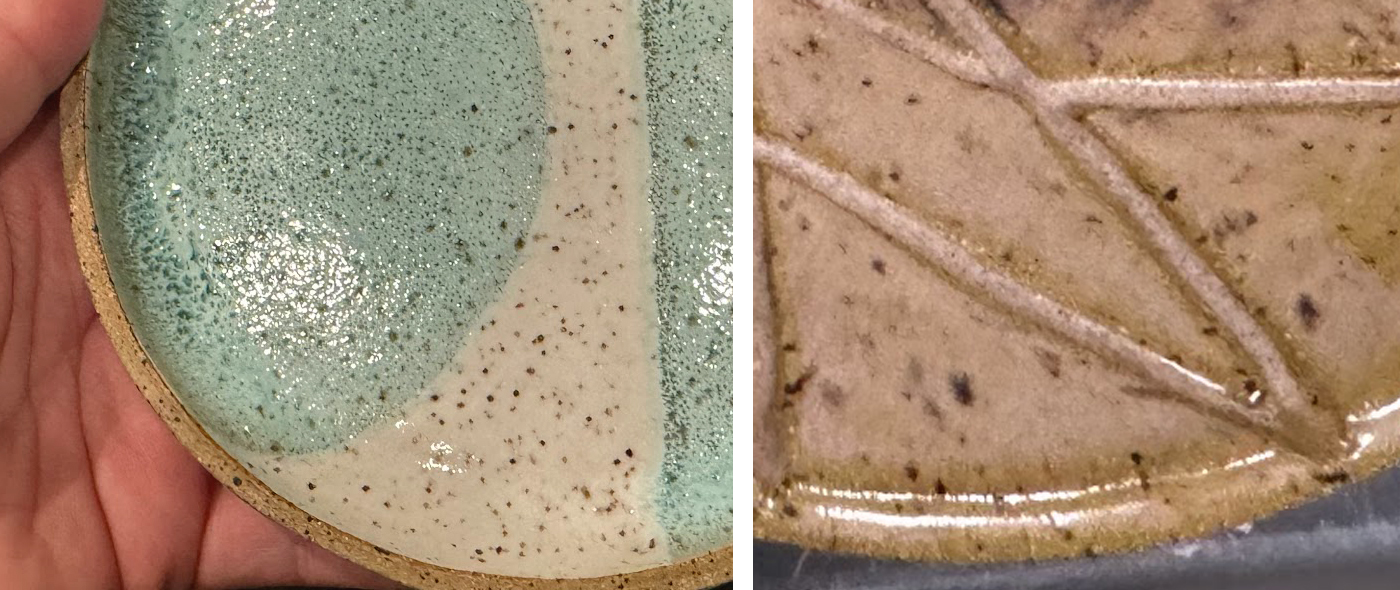

Standard 760 Speckled:

- Cone 6: average shrinkage 13.5%, absorption 3.0%

- My community studio calls this color "sand" for a reason: it looks like wet beach sand when fired because of its grey-ish tan speckled color

- The speckles in this clay don't show through translucent glazes like the ones in 112.

- Very plastic

- Has some fine grog, which is slightly noticeable when throwing

- OK for handbuilding, but doesn't have the same level of stability as clays with more fine grog or larger grogs.

- When I'm slab-building with this clay, I prefer to let my slabs firm up before assembling and reinforcing with coils. Slab-built pieces also need a long, slow dry to minimize warping.

- Marbles well with 112, 211, and 308 - just make sure to dry slowly.

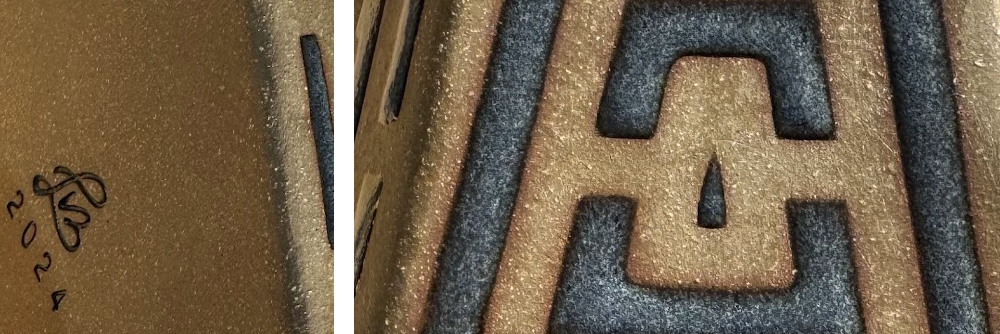

Standard 112 Brown:

- Cone 6: average shrinkage 11.0%, absorption 2.25%

- My community studio calls this "speckled" for a reason: it's light brown with black speckles that can show through glaze formed by granular manganese. It's very popular at my studio for its ability to turn lots of glazes into speckled glazes!

- I find the orange-y salt flashing on this clay especially beautiful, especially in my tape-resist work.

- Medium amount of fine grog: noticeable while throwing and not as supportive while handbuilding as 211 or 308

- When I'm slab-building with this clay, I prefer to let my slabs firm up before assembling and reinforcing with coils.

- Once this clay dries out some, it can be a little finicky to rehydrate back to plastic quickly: best to spray and slam repeatedly and leave overnight, in my experience

- Marbles well with 211, 308, and 760 - just make sure to dry slowly.

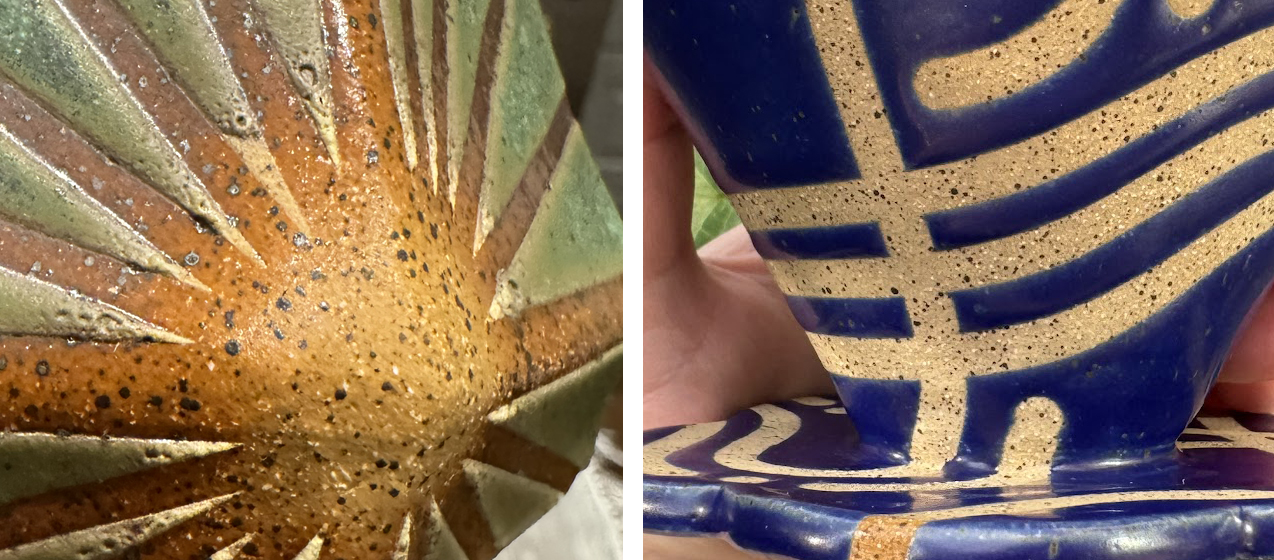

Standard 308 Brooklyn Red:

- Cone 6: average shrinkage 12.5%, absorption 2.0%

- Deep brick red/brown color with light-colored fine grog and sand: there's a huge difference between well burnished pieces (seeing less grog makes it look more maroon) and those where grog is at the surface (much more orange looking). Burnished or not, this color is very polarizing at my studio!

- Turns a murky brown (in my opinion) when covered in clear glaze

- Very plastic and rehydrates easily and quickly from leather-hard back to plastic

- A dream for handbuilding with all that sturdy grog!

- Test glazes for pinholing

- Marbles well with 112, 211, and 760 - just make sure to dry slowly.

Standard 211 Hazelnut Brown:

- Cone 6: average shrinkage 12.5%, absorption 2.0%

- Gorgeous medium brown clay, in my opinion.

- Has a lot of light colored grog that provides a lovely contrast on the surface.

- I love how it looks next to blue glazes and other jewel tones: they pop by contrast!

- Very, very similar working qualities to 308 Brooklyn Red - lots of sturdy grog, very plastic

- Marbles well with 112, 308, and 760 - just make sure to dry slowly.